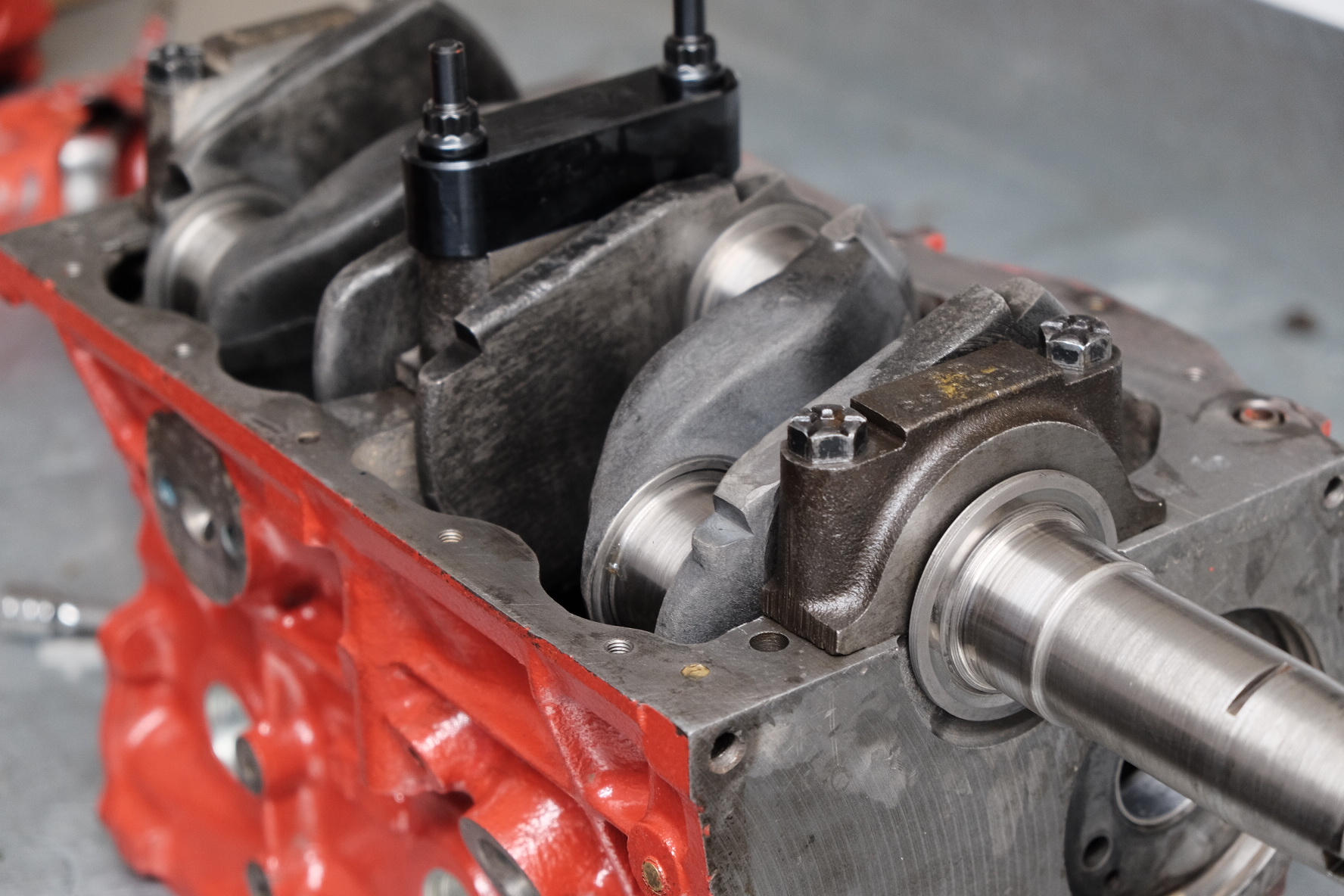

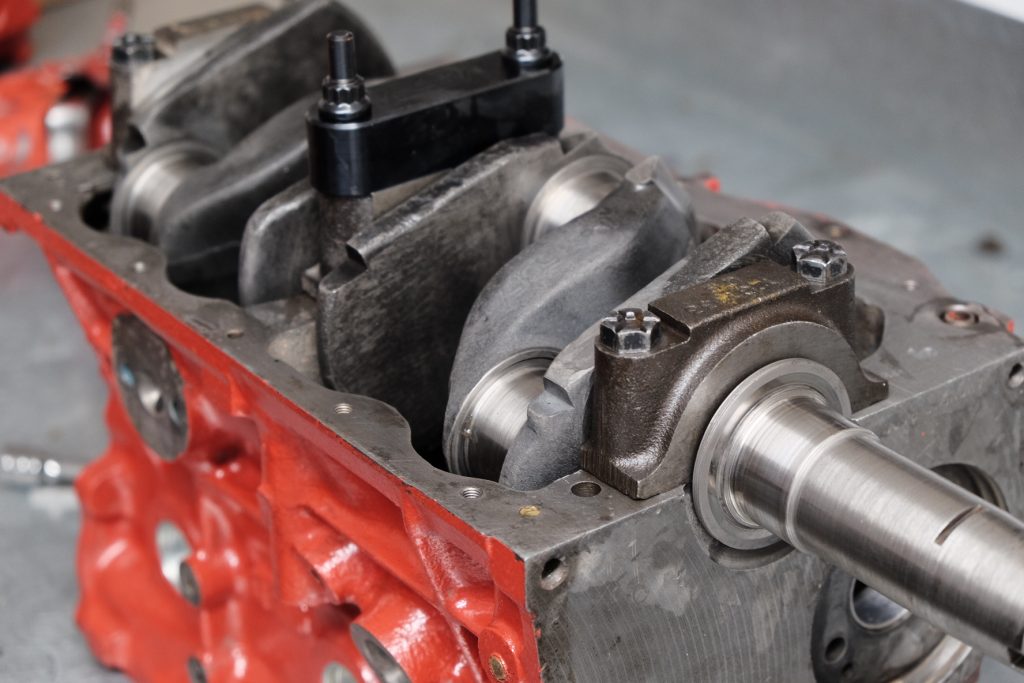

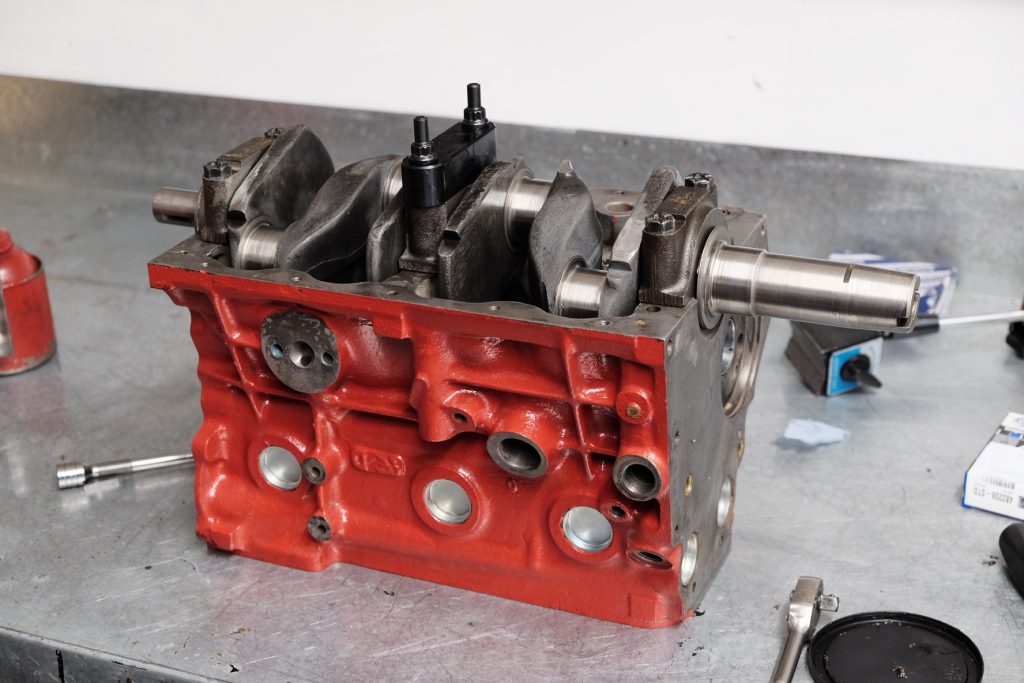

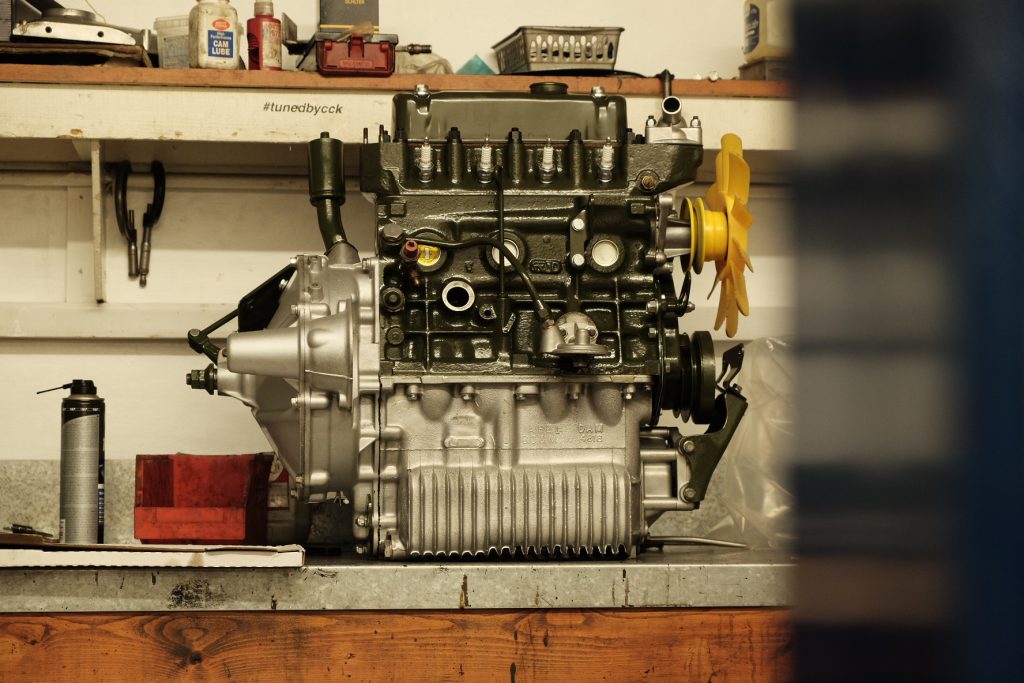

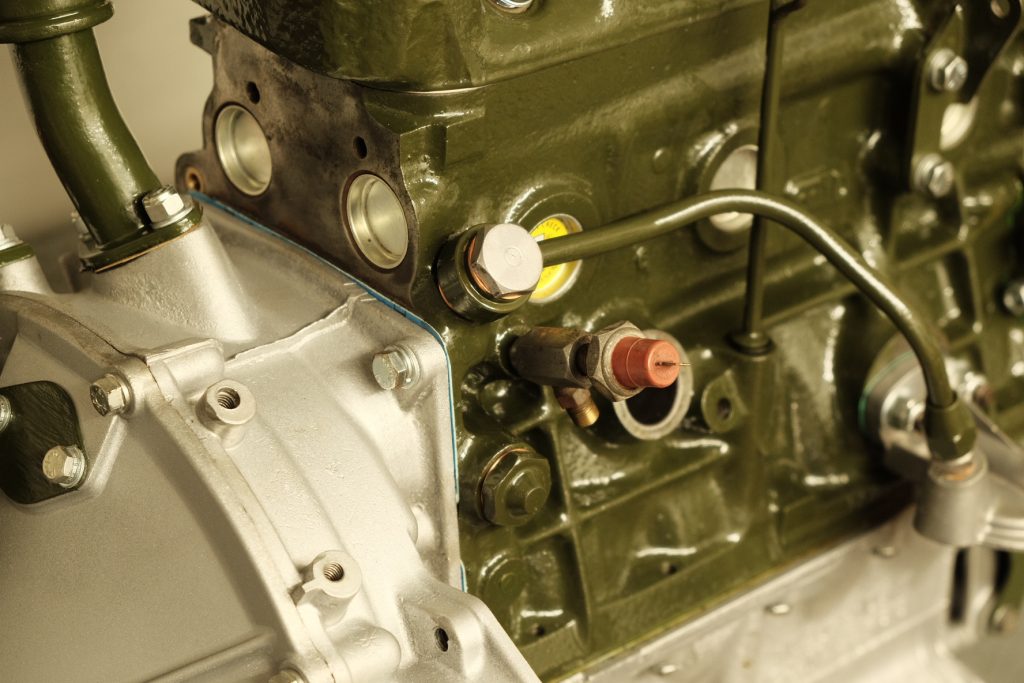

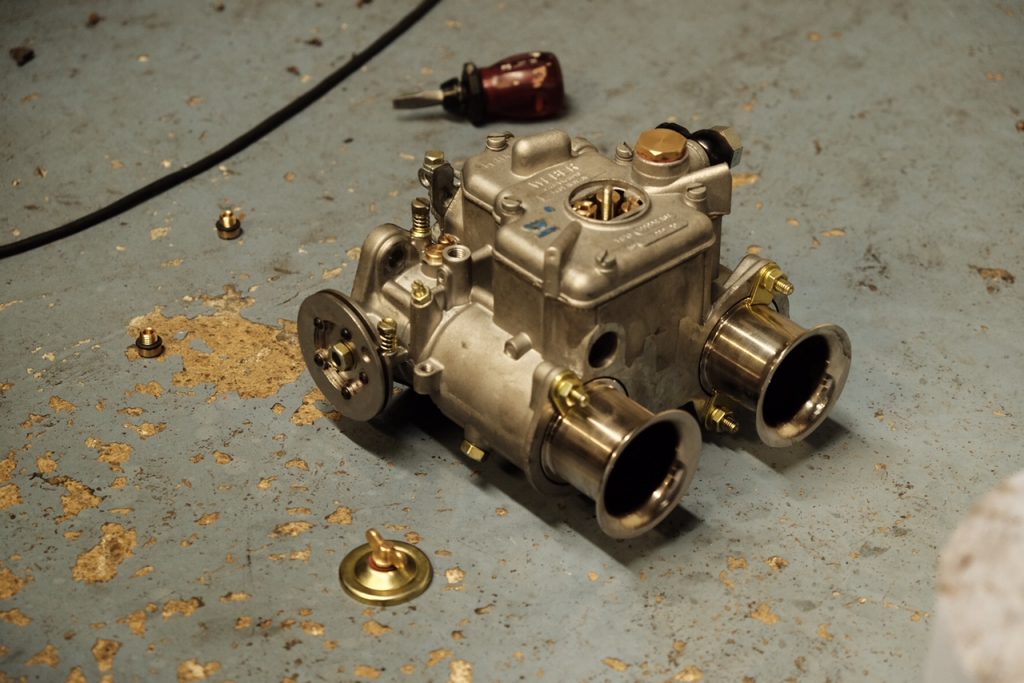

We’ve had a run of classic Mini engine rebuilds lately. Both of these started life as standard 1275cc engines but have been brought up to fast road spec. They both have head work, a camshaft upgrade and roller tip rockers. Both crank assemblies have been balanced including the pistons and con rods. The red engine already had the machine work done but for the green engine we used Southern Rebore Services. They rebored the block to +.040″, ground the crankshaft and refaced the cylinder head.

We are looking forward to seeing them on the rolling road once installed in their respective Minis. If you require a classic Mini engine rebuild, don’t hesitate to get in touch.