Every competition car needs a competition engine so we set about building this 1275cc Mini engine into a Mini rally engine. First, we stripped it down to inspect and measure it. The block and cylinder head were then chemically cleaned. The cylinder head was pressure tested before being ported and modified according to the FIA Group A homologation. It received bronze valve guides and stainless steel competition valves at the correct size. Lastly the head was skimmed to bring the compression ratio up.

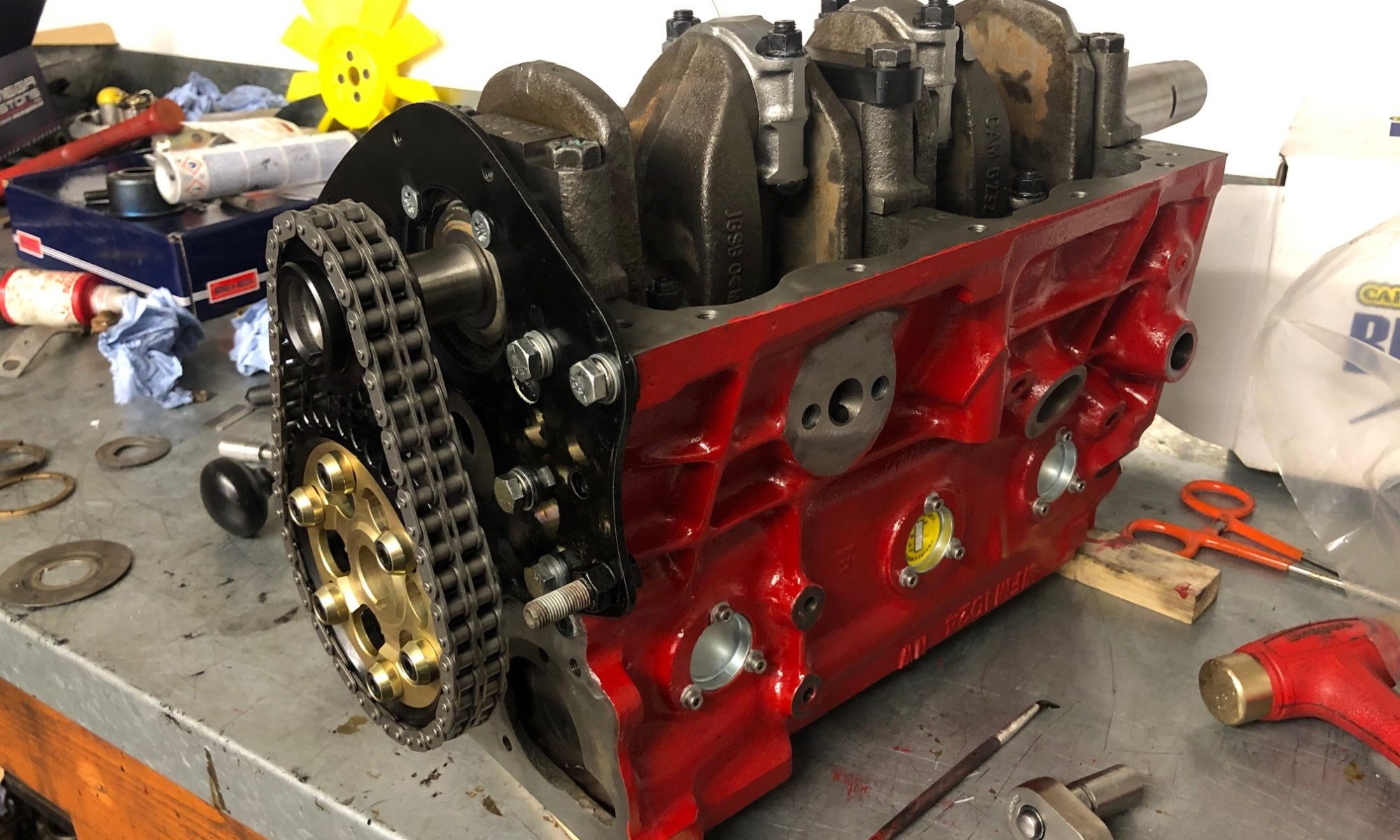

The engine block was rebored by +0.020″ to 1293cc. The maximum capacity for the Group A homologation. The crankshaft was ground and the centre main cap was machined for s strap. All gallery plugs were drilled and tapped for threaded plugs and core plug retainers were fitted. The rotating assembly was balanced before we began assembly. We chose to use an SW10 camshaft with duplex vernier timing gears. Additionally, we chose to use ARP bolts and studs throughout the build. Most of the parts were supplied by Mini Sport.

The gearbox was rebuilt with straight cut close ratio gears. We also installed a limited slip differential and 3.9:1 final drive. The engine was mated to the gearbox and a set of straight cut drop gears were fitted.

When this Mini rally engine build is complete we will install it in the car with the original SPI inlet manifold and throttle body and an aftermarket ECU to get the tuning spot on.