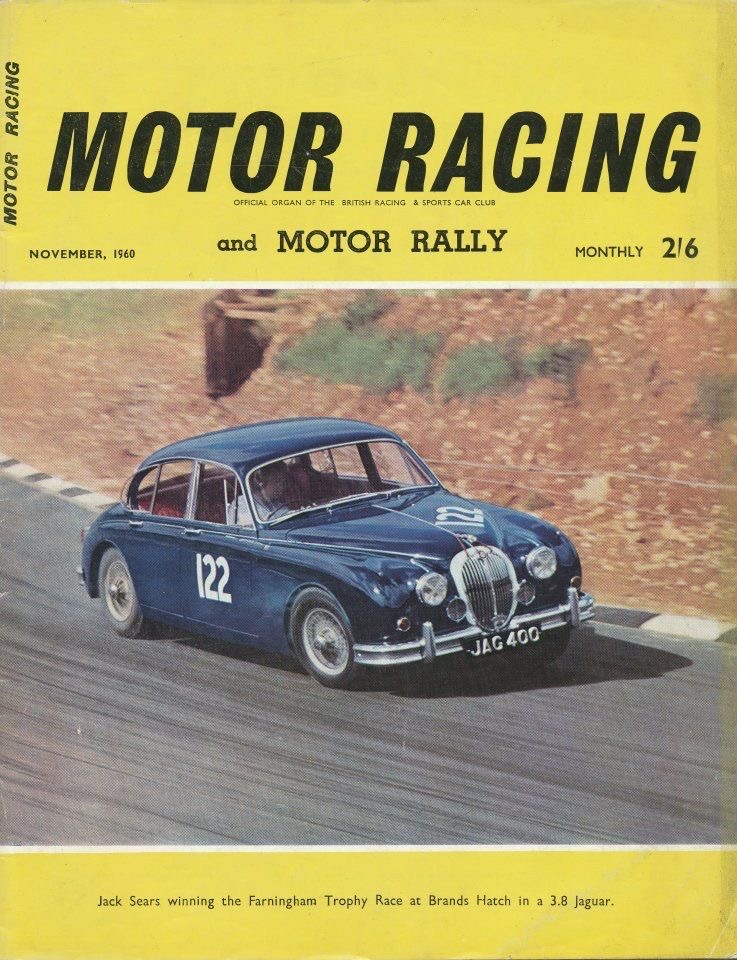

Our good friend Grant Williams was back in for some rolling road tuning. This time however, he brought the recently restored Jaguar Mk2 known as “JAG 400”. The car is an ex-competition car from the early 60s. It was driven in period by Jack Sears and was even tested at Silverstone by Stirling Moss.

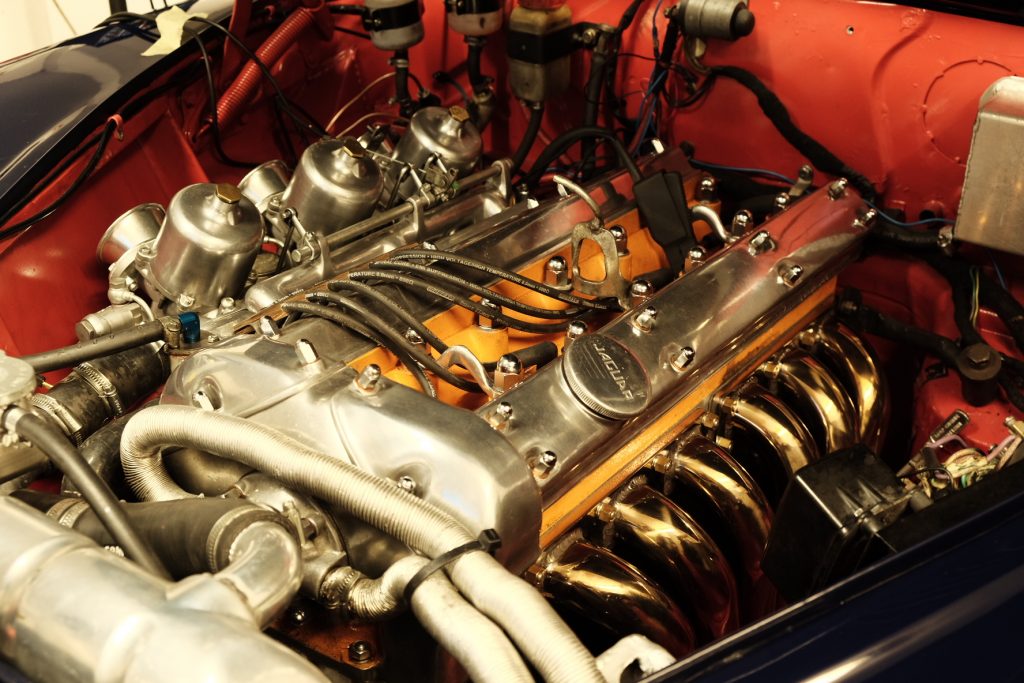

We tuned the Jaguars triple SU carburettors to run with a straight through exhaust. At Goodwood cars are allowed to run without silencers. It is a real privilege to work on cars with such great history and then to see them raced hard on the track. Grant had some rear end trouble on Friday which was quickly dealt with. In Sundays race Grant finished 7th overall and 1st of the Jaguars.